Last updated on November 2nd, 2025 at 08:53 am

You’re cruising down the highway, wind in your helmet, when suddenly your bike sputters, the headlight flickers, and the dash goes dead. You coast to a stop, confused — battery? ECU? Fuel pump?

Nope. Nine times out of ten, it’s something far simpler: an electrical short.

Modern motorcycles are electrical marvels — packed with sensors, ECUs, traction control, and Bluetooth connectivity. But that sophistication comes at a cost. With more wires, relays, and connectors than ever, even the tiniest short can bring the whole system down.

The good news? You don’t need to be a master technician to trace and fix it. You just need the right approach, a bit of patience, and an understanding of how your bike’s electrical system behaves when something goes wrong.

This guide walks you through that — step by step, like a real-world mechanic would.

What an Electrical Short Actually Is

In simple terms, an electrical short happens when electricity takes a path it’s not supposed to.

Instead of traveling through a bulb, ignition coil, or sensor, it finds a quicker route — often straight to the ground or another wire.

That “shortcut” can overload circuits, blow fuses, or even fry sensitive components like the ECU.

It’s like pouring water through a cracked hose — most of it spills out before it reaches the nozzle.

Modern motorcycles use thinner wires and tightly packed connectors to save weight. Great for performance, not so great for durability. Constant vibration, moisture, or even a tight zip tie can expose the copper beneath insulation. One spark, and boom — you’ve got a short.

As bikes get smarter, their weak spot isn’t mechanical anymore — it’s electrical.

Step-by-Step: Finding the Electrical Short

Step 1: Start with the Basics — The Fuse Box

Grab a flashlight and head for the fuse box. It’s usually under the seat or behind a side panel.

If one fuse looks burnt or cloudy, that’s your first clue.

- Replace the blown fuse.

- Switch on the ignition.

- If it pops again immediately, that circuit’s got a short.

Pro Tip: Always carry spare fuses. They’re cheaper than a coffee, and they can save your day mid-ride.

If you’re new to routine maintenance, check our detailed Motorcycle Coolant Change Guide — it teaches other crucial preventive habits riders overlook.

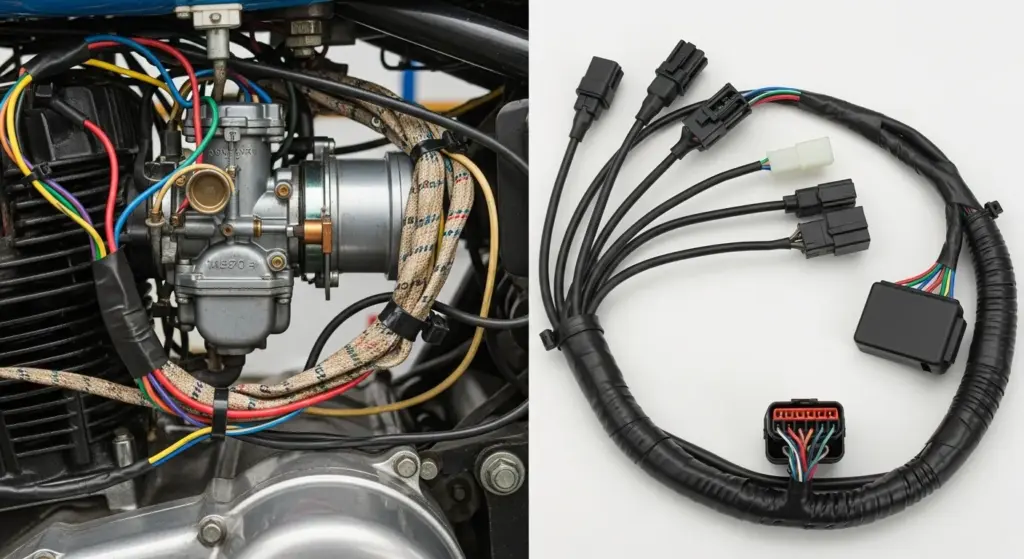

Step 2: Follow the Trail — Inspect the Wiring Harness

Next, visually trace the affected circuit. Most shorts are hiding in plain sight — near areas with movement or friction.

Look carefully around:

- The steering head (wires stretch when turning)

- Under the fuel tank (heat and compression)

- Around the tail section (constant vibration)

If you spot a melted or frayed wire, that’s probably your culprit.

The number of shorts caused by over-tightened zip ties is criminally underrated.

If you’ve faced odd idling or stalling along with electrical hiccups, you might also want to read Motorcycle Backfires – Causes and Fixes to understand how electrical health affects combustion performance.

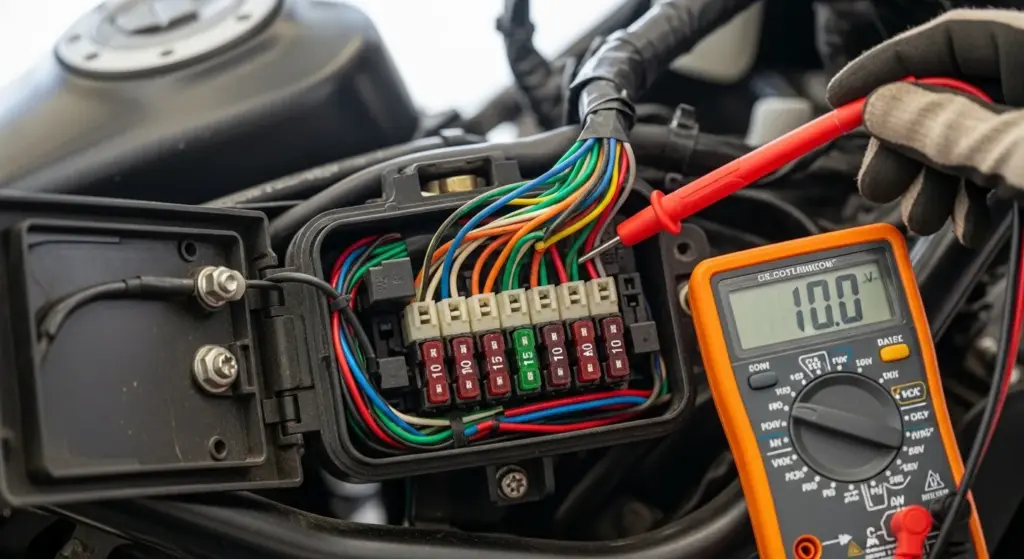

Step 3: Bring in the Multimeter

If nothing obvious shows, it’s time for a bit of detective work.

Set your multimeter to continuity mode.

- Disconnect the battery.

- Touch one probe to the wire, the other to the bike’s frame (ground).

- If the meter beeps or shows continuity, there’s an unwanted connection — a short.

Mark that wire, then follow it along the harness until the reading disappears. You’ve just isolated the section that’s leaking current.

This is slow, methodical work — but it’s the exact process used by factory technicians.

Step 4: Repair the Damage

Found the damaged wire? Here’s how to fix it right:

- Cut away the burnt or exposed section.

- Strip the insulation back neatly.

- Use solder or crimp connectors to join new wire.

- Cover with heat-shrink tubing or electrical tape.

- If you’re near metal, add a sleeve or wire loom for protection.

Then reconnect the battery, replace the fuse, and test again.

If your fuse holds and everything powers up — congrats, you’ve just fixed an electrical short like a pro.

Step 5: Clean the Connectors

Many “shorts” are actually caused by corrosion — especially after rain rides or washing.

Use an electrical contact cleaner to flush out grime and oxidation. Then, apply a thin layer of dielectric grease to seal moisture out.

It’s one of those tiny maintenance habits that prevents massive headaches later.

A $10 tube of dielectric grease is worth more to your wiring than most expensive gadgets.

If your bike has been running hot lately, you can also go through our guide on Diagnosing Motorcycle Overheating Problems in Summer — since heat buildup often worsens insulation damage.

Why Modern Bikes Face More Electrical Issues

Here’s the irony: as bikes evolve, they get both smarter and more vulnerable.

Older bikes relied on mechanical switches and direct wiring. Newer ones are controlled by electronic sensors and data-sharing networks called CAN bus systems.

One shorted wire in a CAN bus can make the ECU misread sensor signals, shutting down entire subsystems — ABS, traction control, even ignition.

It’s efficient tech, but also fragile. The more your bike “thinks,” the more it depends on perfect connections.

In chasing smarter systems, manufacturers may have built bikes that need more human smarts to maintain.

For a glimpse of how complex systems are getting, you can check our review of the Himalayan 750 Specs and Release — it’s one of the most advanced mid-segment adventure bikes coming to the U.S. soon.

Real-Life Scenarios: Where Shorts Hide

1. Under the Seat

The most common location. That’s where the main harness, relays, and connectors live. Seat pressure and aftermarket installs (especially LED kits) cause insulation wear.

2. Handlebar Switches

Constant flexing and exposure to rain make these a short-circuit hotspot.

3. Tail Section

Indicators, brake lights, and plate lights are often routed too close to sharp edges.

4. Battery Terminals

Loose or corroded connections can cause intermittent shorts that mimic ECU failure symptoms.

💡 Tip: Always check aftermarket accessory installations. Sloppy wiring from auxiliary lights or chargers often creates new problems.

Preventing Electrical Shorts in the Future

- Inspect wiring during every oil change. A quick 30-second look saves hours later.

- Avoid high-pressure washing near the battery and connectors.

- Secure wires loosely. Leave room for vibration — tight doesn’t mean safe.

- Use protective loom tubing for added insulation.

- Disconnect accessories properly when washing or servicing your bike.

You can explore more preventive maintenance walkthroughs in the Motorcycle Issues section — it’s packed with practical insights for real-world riders.

When to Seek Professional Help

If the short lies within the ECU or behind sealed harnesses, it’s best to let a certified technician handle it.

You don’t want to void warranties or risk damaging control modules.

Still, don’t underestimate your own ability — tracing visible wires and checking fuses is well within a rider’s reach.

Confidence grows when you fix things yourself — that’s half the joy of motorcycling.

Bonus: Electrical Shorts in Adventure & Dirt Bikes

Adventure bikes and dirt bikes face extra challenges — mud, water crossings, and constant vibration.

Even minor exposure can corrode connectors.

If you’re into off-roading, check our Dirt Bike Beginner’s Guide for tips on wiring protection and waterproofing after river crossings or heavy rains.

Quick Reference: Electrical Short Troubleshooting Table

| Step | Action | Result / Goal |

|---|---|---|

| Check fuses | Identify blown circuits | Confirm short presence |

| Visual inspection | Find frayed or melted wires | Locate likely culprit |

| Multimeter test | Detect continuity to ground | Pinpoint faulty wire |

| Repair & insulate | Replace damaged section | Restore clean circuit |

| Clean connectors | Prevent future corrosion | Long-term reliability |

These steps aren’t just theory — they’re the same diagnostics you’d pay hundreds for at a workshop.

Final Thoughts

Electrical shorts on modern bikes might sound intimidating, but they’re completely solvable once you understand how electricity flows — and where it shouldn’t.

Don’t let a dead dashboard or flickering headlight send you running to the shop. Sometimes, it’s just one hidden wire crying for attention.

And when you finally hear that engine fire up again after fixing it yourself, there’s a special kind of satisfaction that no service bill can match.

If you’re tackling other maintenance tasks, explore our Motorcycle section for guides on Clutch Slipping Causes and Fixes and other essential rider topics.